Forging Tomorrow's Foundations, Today.

MARINE (OFFSHORE) DCM

Marine DCM (Deep Cement Mixing) is a highly effective soil improvement method utilized in soft soil conditions, including clay, sand, and organic soil. It involves injecting a cement paste mixture, composed of cement and water, into the soft soil at low pressure. The cement paste is agitated with a specialized device, resulting in the formation of column piles through cementation of the original soil. This innovative technique serves various purposes, such as foundation work, waterproofing, and earthwork.

One of the key advantages of Marine DCM is its versatility, making it suitable for a wide range of applications. It can be applied in projects with workable water depths of up to -34 meters, making it ideal for marine construction in deeper areas. Additionally, this method stands out as an environmentally friendly approach, generating minimal sound and vibration and causing minimal disruption to the adjacent soil, thereby earning high credibility in the industry.

The cement paste used in Marine DCM is produced in a controlled environment at a plant and then transported to the D.C.M. barge using pressure pumps. This process ensures the consistent quality and performance of the cement mixture, further enhancing the reliability of the technique.

The application of Marine DCM has been successfully demonstrated in various projects, including the 3RS Project (C3206) and the IWMF Project in Hong Kong, the Yeosu New North Port Project, and the Saemangeum New Harbor Project, among others. These projects have shown promising results and have been completed within specific periods, showcasing the efficiency and effectiveness of the Marine DCM method.

The performance of Marine DCM is evaluated based on factors like the mixing area (m2) and the compressive strength achieved in one axial, which are key indicators of its effectiveness in stabilizing and improving the soil conditions. With its proven track record, Marine DCM continues to be a preferred choice for soil improvement works in various marine and land-based projects, providing a strong foundation and sustainable solution for construction endeavors.

DCM is a kind of soil improvement work method using cement paste which is a mixture of cement and water in the soft soil. While injecting cement paste which is a mixture of cement and water into the soft soil (clay, sand, organic soil) with low pressure, we make agitation of soft soil and cement paste by special agitation device to form column piles by cementation of the original soil and this can be used for various purpose such as foundation work, waterproof work, earthwork etc.,

Workable water depth is up to -42M from -3.SM and this method is a pro-environmental method with little sound and little vibration and is giving little impact to adjacent soil to have high credibility.

Cement paste is made in the plant and sent to the DCM barge by pressure pump. The targeted soft soil area is evenly agitated, mixed, hardened, and consolidated to secure bearing capacity not less than the required figure.

The functioning of DCM

Method

To serve as a foundational support for upper structures such as harbor facilities or inner walls, the initial step involves a worker mixing a stabilizing cement-based liquid with the weak soil found at the seafloor. Chemical solidification is then utilized to ultimately transform the entire area into a solid and stable foundation.

Typical Applications:

The DCM method has proven successful in a wide range of projects and is typically employed as a ground improvement system in the following scenarios:

Foundations for the construction of ports, airports, embankments, roads and Industrial projects.

In situations where various structures need to be constructed on compressible, saturated soils, such as soft clay, issues like bearing capacity and excessive settlement often pose significant challenges. Deep Cement Mixing (DCM) is a suitable method to address these challenges effectively.

The primary objective of DCM is to enhance the shear strength of the soil by mixing it in-situ with a cement grout. Utilizing the ground improvement technique of the DCM method enables excavation work, embankment construction for highways and reservoirs, and the use of soil foundation systems in soft soil environments.

CHARACTERISTICS OF DCM

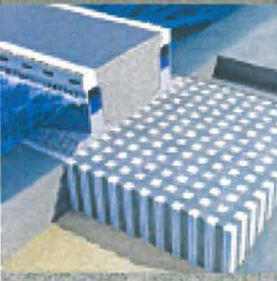

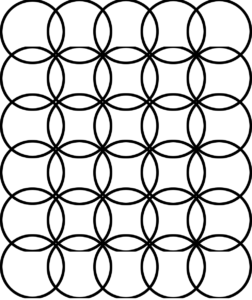

DCM is Mixing cement binder with in-situ soil forming individual columns or in a block.

Column sizes of 1.0m to 1.4m in diameter and our exclusive ship make it possible to work in deep water up to -65m.

Two main components of DCM serve the following functions:

• Increase shear strength of soil

• Reduce permeability of soil

Single Type

Wall Type

Block Type

Grid Type

EQUIPMENTS

No. | EQUIPMENT | SPECIFICATION |

1 | Multiple Rig | 35 ~ 54 m |

2 | Auger | 350 PW |

3 | Rod | 28 ~ 44 m |

4 | Hose Pump | SPX65 |

5 | Mixing Rod | ⌀ 1,300 |

6 | Agitator | ⌀ 5,000 |

7 | Main Winch | 5 Ton |

8 | Hydraulic Station | 5 Ton |

9 | Air Compressor | CFM 800 |

10 | Generator | 700 Kw |

11 | Operation Room | 3,000 x 10,000 x 2,400 |

12 | Electric Room | 3,000 x 10,000 x 2,400 |

Exclusive Barge Installation Rig

Type of Base Machine

Weight

Mast Height

Typical Auger Drive

Rotation Speed

Penetration Speed

Maximum Installation Depth

Typical Grout Pump

Flow Rate

Injection Pressure

Typical Cement Mixing Plant

Cement Silo

Mixer

Agitator

Hose Pump

Operating System

GPS

Auto Recording System

Generator

Main Generator

Sub Generator

Required Service Vessel

Bulk Carrier

Tug Boat

Transportation Service Boat

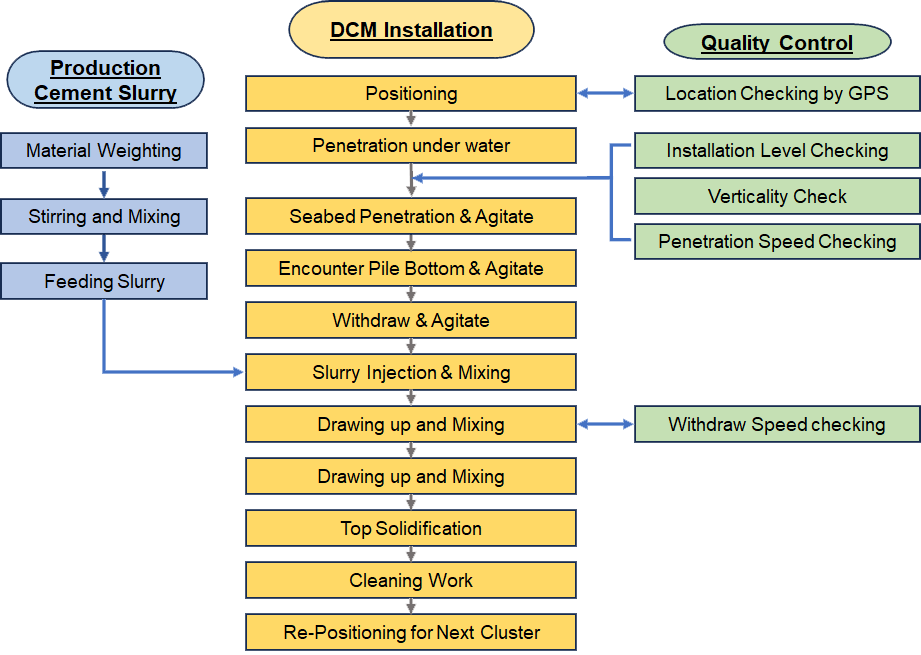

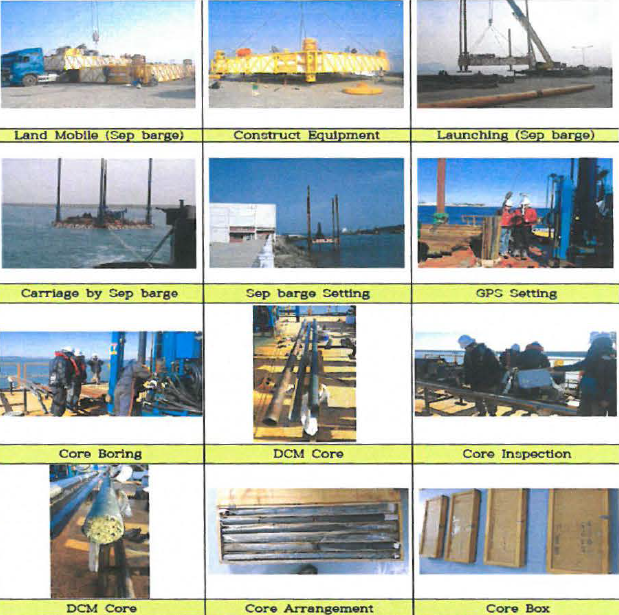

DCM WORK SEQUENCE

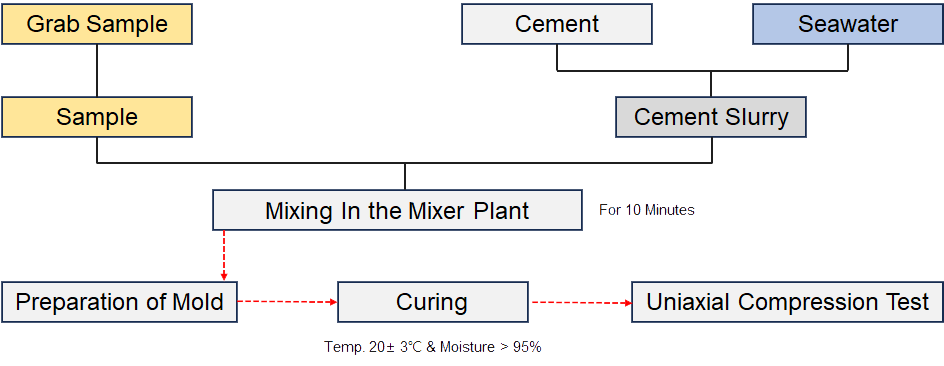

LABORATORY TEST

Prior to DCM Construction, the test should be done to determine cement and water ratio of mixture considering test result.

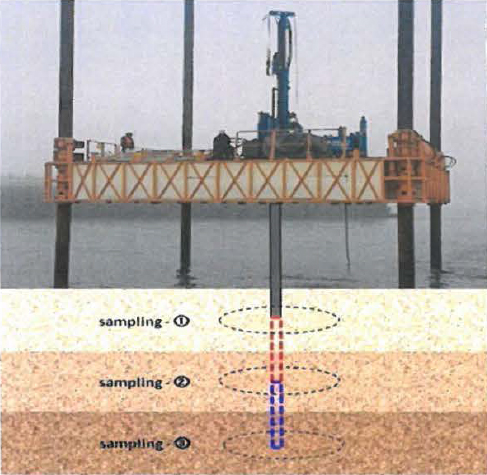

1) Soil Sampling

The commonly used method for soil sampling would be based on soil types and the sampling area will be dependent on the soils and topography as shown on below Figure 2. Once the sampling area is determined, a sufficient number of cores should be taken to acquire representative samples for mixture’s strength testing at 7 days, 14 days and 28 days.

Self Elevated Platform Barge

Length 12 m

Width 12 m

Height 1.6 m

Leg 4 ea

Diameter 406

Length 30 m

Bottom 2000

Tug Boat (450 HP) 1 Ship

Boring Machine (4000 SD) 1 Set

D3 core Sampler 1 Set

Engine Pump 1 Set

D3 Core Sampler 1 Set

Laboratory Mixing and Mold Preparation

UNIAXIAL COMPRESSIVE TEST

Specimens from mold are prepared by cutting them to the specified length and are thereafter ground and measured. There are high requirements on the flatness of the end surfaces in order to obtain an even load distribution. The testing is in accordance with relevant procedures such as KS F 2314. See Figure 4.

Cement Transportation Method

Bulk Carrier is mobilized to supply bulk cement from land to the bulk cement Silo on the main barge as shown below.

The delivery capacity of bulk carriers is 270 tons to 420 tons each time.

Mixing Cement Slurry

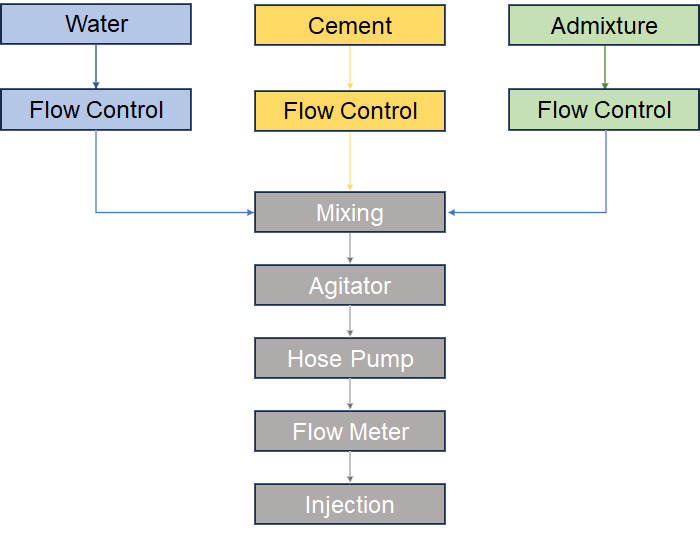

The cement slurry used for soil treatment shall be premixed in a mixing plant which combines the cement, water and admixture together according to the pre-determined proportions. Cement shall comply with the project requirements for Ordinary Portland Cement or other applicable cement such as slag cement, etc., based on the laboratory testing results executed prior to construction.

The mixing plant shall comprise colloidal mixers, volumetric screw feeders, and flow controllers. Dry materials shall be stored in silos and fed by screw feeders to the colloidal mixers for agitation and circulation. The mixed cement slurry shall be transferred to an agitator with additional mixing and then fed to the DCM rig as shown below.

Installation of DCM Clusters

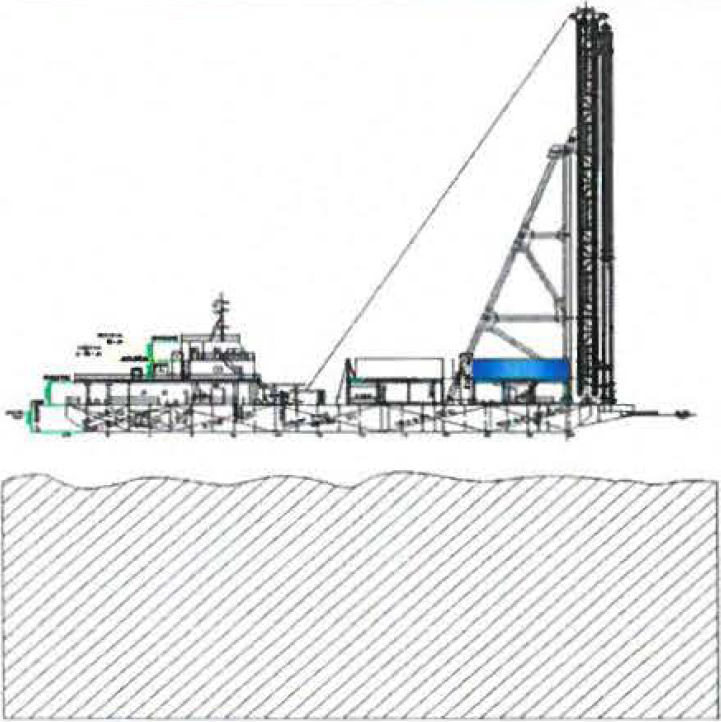

1) Positioning of DCM Barge and Setting out of DCM Clusters

The control of barge position and design location of DCM clusters will utilize the GPS system. A Barge GPS receiver and telemeter will be installed for positioning the barge. Reference station will also be set up at the nearby area for referencing and calibrating all geographical data In accordance with Grid System. The geographical data will be transferred to computing system for real time monitoring of the position of the clusters during installation works.

2) Installation of DCM Clusters

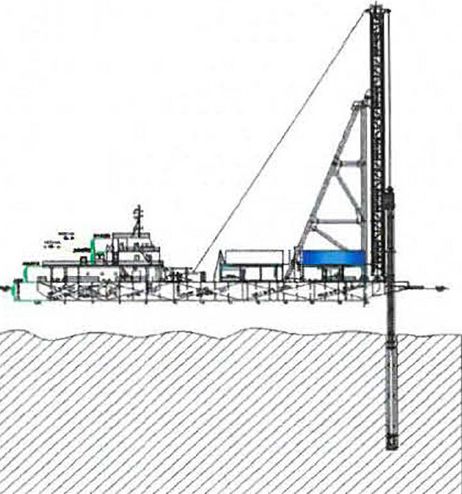

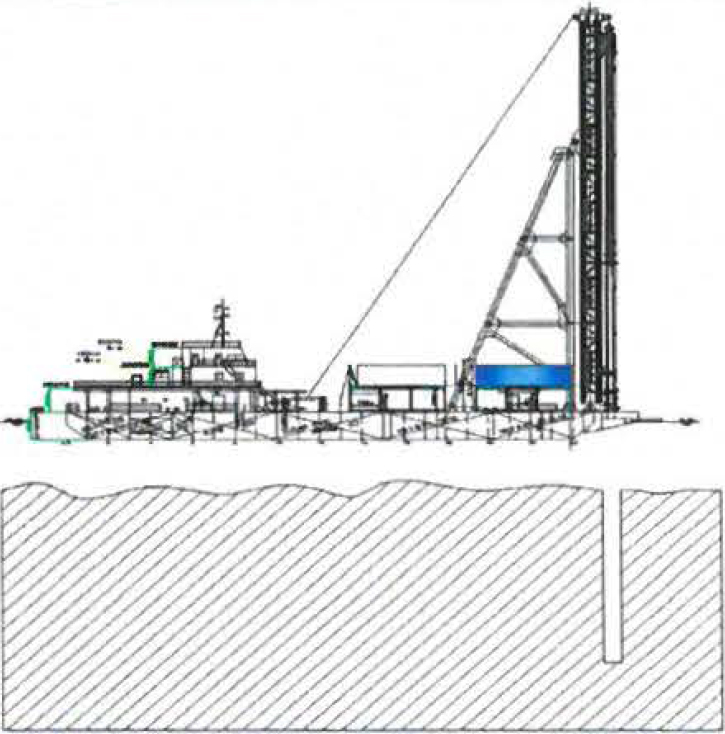

DCM is a kind of soil improvement work method using cement paste which is mixture of cement and water in the soft soil. While injecting cement paste which is mixture of cement and water into the soft soil (clay, sand, organic soil) with low pressure to make agitation of soft soil and cement paste by special agitation device to form column piles by cementation of the original soil workable water depth is up to -34 meter and this method is a pro- environmental method with little sound and little vibration and is giving little impact to adjacent soil to have high credibility. Cement Paste is made in the plant and sent to the DCM barge by pressure pump. The targeted area of soft soil is evenly agitated mixed and hardened and consolidated to secure a bearing capacity not less than the

required figure.

Penetration Under Water

Drilling & Mixing

Drilling & Slurry Injection & Mixing for Stabilization of the bottom of Clusters

Slurry Injection & Mixing While Withdrawal

Cleaning & Repositioning for Next clusters

Drilling & Mixing

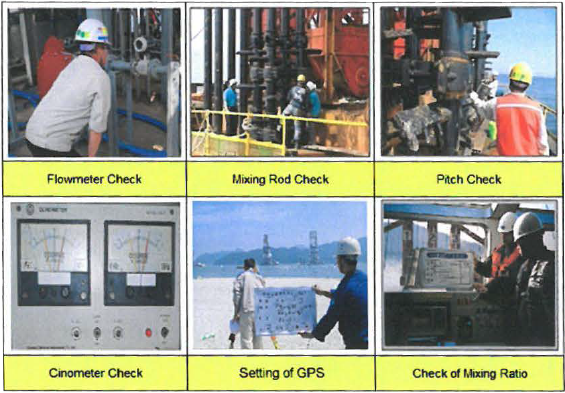

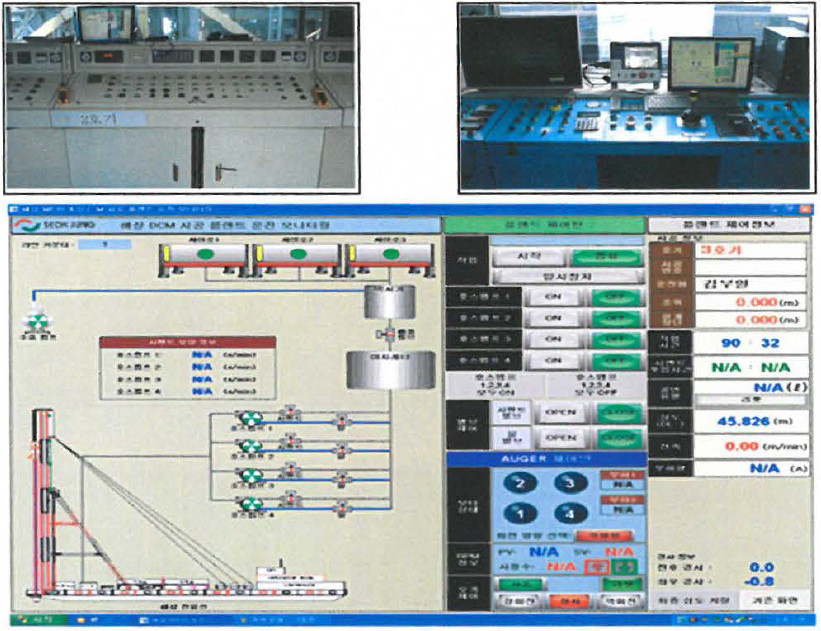

Operation & Control System

The DCM Plant is operated via computerized real-time monitoring and control system as shown on above. Each DCM Rig is operated by each operator individually. The monitoring screen comprised of four parts as described next pages.

Part 1: General Operation Monitoring for Marine DCM Plant

It shows general operation condition such as water pump, cement silo, mixer, agitator, hose pump, valves and DCM construction plant.

Part 2: Control Monitoring for Marine DCM Plant

The plant is operated by control switches which have following functions:

- Start, end and stop for plant operation

- On-Off for each no. of Hose Pump

- Open-Close for cement valve and water valve

Part 3: Control Monitoring for Augers of Marine DCM Plant

It shows the mechanical and operation condition for augers operated individually by control switches which have following functions:

- Mechanical Condition for Auger Motors

- Direction of Rotation

- RPM of Auger

Part 4: Control Monitoring for Augers of Marine DCM Plant

As shown on the figure in Part 4, It shows the information for plant operations and DCM construction and site conditions.

- Number of Plant and Operator and working t ime

- Design Information including number of column, designed level and depth.

- Injection Time for Cement

- Cement Paste Quantity by Flow meter

- Installation Depth

- Electrical Resistance (A) occurred during drilling

- Running Speed of Rod

- Data of Clinometer

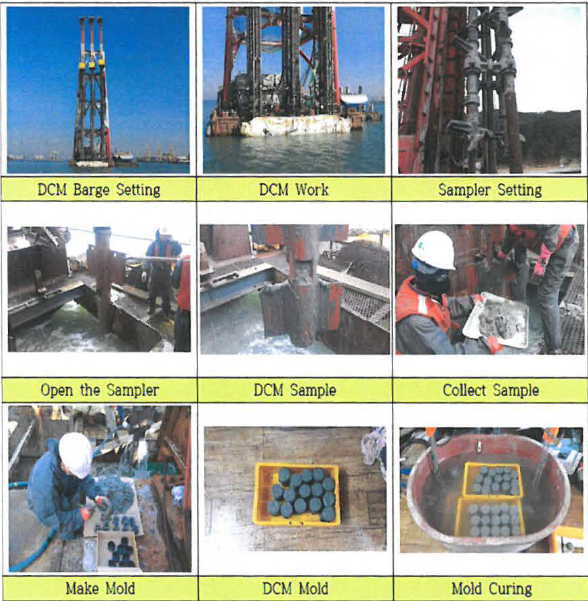

Sampling of DCM Clusters in unconsolidated Condition

Strength Test of DCM Clusters Completed

QUALITY CONTROL

For production quality control, the real time monitoring of rotational speeds and penetration / withdrawal rates of the mixing shafts should be performed. The total quantity of cement slurry injected should be in accordance with the mix design established during the early stage of construction. The cement paste injection rate should be constantly monitored, calculated, and controlled. For production quality control the real time monitoring of the slurry injection rate should be performed.

The spacing of rigs can be adjusted horizontally to suit the design pattern. The horizontal alignment should be accurately set by using of GPS system before beginning DCM installation.

The preliminary alignment should be positioned by adjusting the anchors of DCM barge.

The vertical alignment should be monitored by two measures – the front rear and the left-right.